Wheel size 200 or 250 mm

Wheel size 300 or 350 mm

Wheel size 150 or 180 mm

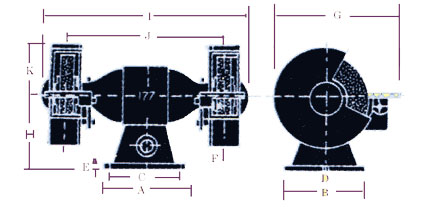

Bench Grinders are used for grinding of tools, tips, light grinding etc. Each machine is equipped with Two Nos. Grinding Wheel .

|

Model |

H.P |

K.W |

Ph. |

R.P.M |

Wheel Size |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

Approx |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

BG-41 |

0.25 |

0.18 |

1 |

2800 |

100 |

130 |

130 |

108 |

108 |

13 |

39 |

150 |

115 |

330 |

258 |

65 |

9 |

|

BG-61 |

0.33 |

0.25 |

1 |

2800 |

150 |

230 |

233 |

204 |

204 |

23 |

55 |

227 |

168 |

472 |

380 |

95 |

32 |

|

BG-71 |

0.50 |

0.37 |

1 |

2800 |

180 |

230 |

233 |

204 |

204 |

23 |

58 |

248 |

171 |

480 |

385 |

107 |

34 |

|

BG-581 |

0.50 |

0.37 |

1 |

2800 |

200 |

230 |

233 |

204 |

204 |

23 |

60 |

283 |

171 |

480 |

385 |

120 |

38 |

|

BG-81 |

0.75 |

0.55 |

1 |

2800 |

200 |

227 |

232 |

200 |

205 |

27 |

60 |

283 |

202 |

500 |

404 |

120 |

42 |

|

BG-101 |

1.00 |

0.75 |

1 |

2800 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

57 |

|

BG-43 |

0.25 |

0.18 |

3 |

2800 |

100 |

130 |

130 |

108 |

108 |

13 |

39 |

150 |

115 |

330 |

258 |

65 |

9 |

|

BG-63 |

0.33 |

0.25 |

3 |

2800 |

150 |

230 |

233 |

204 |

204 |

23 |

55 |

227 |

168 |

472 |

380 |

95 |

30 |

|

BG-73 |

0.50 |

0.37 |

3 |

2800 |

180 |

230 |

233 |

204 |

204 |

23 |

58 |

248 |

171 |

480 |

380 |

107 |

32 |

|

BG-583 |

0.50 |

0.37 |

3 |

2800 |

200 |

230 |

233 |

204 |

204 |

23 |

60 |

283 |

171 |

480 |

385 |

120 |

120 |

|

BG-83 |

0.75 |

0.55 |

3 |

2800 |

200 |

227 |

232 |

200 |

205 |

27 |

60 |

283 |

202 |

500 |

404 |

120 |

42 |

|

BG-103 |

1.00 |

0.75 |

3 |

2800 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

47 |

|

BG-113 |

1.00 |

0.75 |

3 |

1420 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

48 |

|

BG-123 |

2.00 |

1.50 |

3 |

1420 |

300 |

255 |

300 |

215 |

255 |

30 |

92 |

405 |

220 |

610 |

460 |

170 |

102 |

|

BG-143 |

3.00 |

2.25 |

3 |

1420 |

350 |

245 |

264 |

208 |

228 |

40 |

112 |

490 |

250 |

720 |

495 |

220 |

123 |

General Tolerance ± 0.50 %

Dimensions, details etc. are subject to change as the quality of machines is improved constantly

@ 2020 ELMACO VIJAY. All Rights Reserved | Website Design & Development by SIB Infotech