Split lapping machine

Single Sided Jewellary Polishers

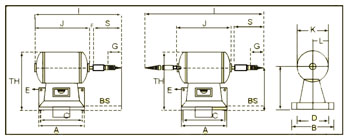

Model |

H.P |

K.W |

R.P.M |

Ph. |

"S" |

A |

B |

C |

D |

E |

F |

G |

H |

TH |

I |

J |

K |

BS |

Approx.

Nett WT. in Kg. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

VMT-71 |

0.25 |

0.18 |

3000 |

1 |

110 |

130 |

130 |

108 |

108 |

8 |

- |

45 |

115 |

170 |

353 |

232 |

106 |

170 |

7 |

VMT-73 |

0.33 |

0.25 |

3000 |

1 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

21 |

VMT-75 |

0.50 |

0.37 |

3000 |

1 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

21 |

VMT-77 |

0.75 |

0.55 |

3000 |

1 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

25 |

VMT-79 |

1.00 |

0.75 |

3000 |

1 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

26 |

VMT-74 |

0.50 |

0.37 |

3000 |

3 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

19 |

VMT-76 |

0.75 |

0.55 |

3000 |

3 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

21 |

VMT-78 |

1.00 |

0.75 |

3000 |

3 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

22 |

Model |

H.P |

K.W |

R.P.M |

Ph. |

"S" |

A |

B |

C |

D |

E |

F |

G |

H |

TH |

I |

J |

K |

BS |

Approx. Nett WT. in Kg. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

VMT- 81 |

0.25 |

0.18 |

3000 |

1 |

110 |

130 |

130 |

108 |

108 |

8 |

- |

45 |

115 |

170 |

474 |

232 |

106 |

170 |

8 |

VMT- 83 |

0.33 |

0.25 |

3000 |

1 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

21 |

VMT- 85 |

0.50 |

0.37 |

3000 |

1 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

21 |

VMT- 87 |

0.75 |

0.55 |

3000 |

1 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

26 |

VMT- 89 |

1.00 |

0.75 |

3000 |

1 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

27 |

VMT- 84 |

0.50 |

0.37 |

3000 |

3 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

20 |

VMT- 86 |

0.75 |

0.55 |

3000 |

3 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

22 |

VMT- 88 |

1.00 |

0.75 |

3000 |

3 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

23 |

General Tolerance ± 0.50 %

Dimensions, details etc. are subject to change as the quality of machines is improved constantly

@ 2020 ELMACO VIJAY. All Rights Reserved | Website Design & Development by SIB Infotech